Product Design Guidelines for Assembly--Tolerance requirements

- Jussi Zhong / plastic mold expert in Shenzhen

- 2016年1月3日

- 讀畢需時 1 分鐘

More strict tolerance parts, replacement parts and manufacturing cost is higher, the higher cost of the product accordingly.

Reasonable gaps among components; In generally, without affecting product functionality and quality, the gap should be as large as possible.

Simplify product assembly relationship; reduce the steps in the chain so as to reduce the number of cumulative tolerances.

Using the positioning feature; positioning feature enables the parts fitted exactly in products, this feature dimensions need be strict control, other unimportant dimensions can allow loose tolerances.

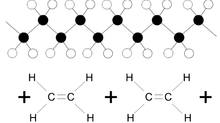

Using dots or lines instead of a plane; when cooperation between the two parts having relative motion relationship, you can substitute the plane using points or lines, to avoid deformation of the plane or higher surface roughness treatment to move parts, thus no part flatness and surface roughness strict tolerance requirements, and then allowed to loose tolerances.

留言