Hole Design for plastic part prototype

- Jussi Zhong / plastic mold expert in Shenzhen

- 2016年1月28日

- 讀畢需時 1 分鐘

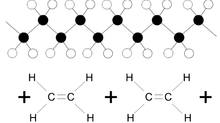

From considering the mold fabrication processing, the best hole made regular shape and simple hole, as far as possible not to make complex shaped holes with a diameter not too small, holes depth and diameter ratio should not be too large, because thin and long metal easily broken, deformed.

Hole depth dimension

Gaps among holes and the parts edge

Avoid the roots is too thin for blind hole

Holes should be far away from the area by the loaded

The flange of the hole increase the strength

Do best to avoid side holes to be perpendicular with release direction in molding processing

留言