Product design guideline--to reduce the number and type of fasteners

- Jussi zhong / plastic mold expert in Shenzhen

- 2015年12月27日

- 讀畢需時 1 分鐘

The function of fasteners are to fix the parts, no extra part function and quality.

Using the same type of fasteners; reduction for a variety of types of fasteners control in the design and manufacturing process ;brings cost advantages on the purchasing; reduce the types of aids on the assembly line and to prevent assembly errors.

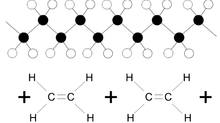

Using a snap to instead of fastener; the most economical and most friendly way assembly, using a snap also can save a lot of assembly time and assembly costs.

Designed to avoid the disperse fasteners; design the fastener as a whole, can reduce the type of fastener, reduced assembly time and improve the assembly efficiency.

Treat the studs and nuts as a last resort; the four commonly used method for assembling costs: snap lowest cost, followed by Latin cost, high cost screws, bolts and nuts of the highest cost.

留言