The processing in the plastic mold design

- Jussi Zhong / plastic mold expert in Shenzhen

- 2015年12月1日

- 讀畢需時 1 分鐘

In this mold design process, we need compromise all the elements to choose reasonable structures, to implement our goal--formed plastic enclosure we prefer to.

Pattern with 3D software Per the 2D drawing layout, to do further design in 3D drawing

Split plastic parts Select correct parting line, consider the sealing distance, construct datum plate, balance the injection pressure, shut off area to be handled, avoid the sharp steel happened, cosmetic appearances etc.

The strength of the mold components and whole mold Check whole and partial area strength in the molding processing

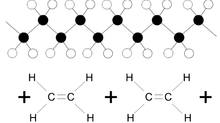

The mold components design The components are divided into 2 types, forming components and structure components.

The insert split consideration: sharp or thin steel, easy to manufacture, easy to modify dimension and maintenance, strength of inserts, easy to assemble, no affect on appearance, cooling efficiency

Compromise the layout between ejectors and cooling channels In generally, the ejectors will be put first, then cooling channels, next is adjust ejectors

3D drawing convert to 2D drawing to manufacture

留言