The procedure in the plastic mold design process

- Jussi Zhong / plastic mold expert in Shenzhen

- 2015年11月22日

- 讀畢需時 1 分鐘

Plastic parts or samples analysis

Study the plastic part shape, dimensions, tolerances and part cosmetic surfaces

Confirm the injection machine model and relevant data

Pattern parts and layout confirm

Consider part weight and injection machine capacity, precision of the part, how to deal with the undercut features etc

Cavity and moldbase steel selected

Decide the Parting lines on the plastic part

Don't affect the part appearance, be benefit to the part precision and mold fabrication, especially for the cavity fabrication

Confirm the slider and lifter structure

Moldbase and standard components selected

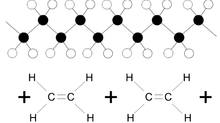

Feed system design

Air venting system design

Eject system design

The main components drawings draft

Check the design drawings

Leader sign on drawings to release drawings fabriction

留言