Air venting system in the plastic mold design

- Jussi zhong / plastic mold expert in Shenzhen

- 2015年11月19日

- 讀畢需時 1 分鐘

Venting can not be ignored aspect in the mold, if venting is harmful trend in the plastic molding, air in the cavity will withstand a big pressure, this will stop melt resin rapid filling in the cavity, and compressed air will create high temperature, possible cause the resin burned.

In the high injection speed, high temperature, high injection pressure and thick thickness, the air will be compressed into plastic resin internally, cause air trap etc. defects. especially in the rapid molding, there are higher requirements for venting system.

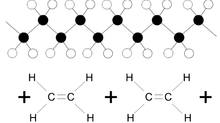

They are 2 ways to add venting on the mold, one is to add it on parting line surfaces, another way is to add on insets or the movable components.

the venting grooves width will be 1.5-6 mm, deep 0.005-0.06 mm (depend on the resin type ), far away from part 1.5-6 mm

留言