How to prevent the crack on the PC parts when we run molding (1)

- Jussi Zhong / plastic mold expert in Shenzhen

- 2015年10月22日

- 讀畢需時 1 分鐘

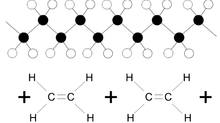

Sometimes we will find some plastic part crack by itself, no external force. Most of them are because of the big internal stress in the plastic part, which is generated in the molding process. Let's take a look how many elements influence it in the molding process.

Mold temperature: increase the mold temperature could reduce the internal stress. For PC material, mold temperature could be controlled within 80-110 degrees Celsius, if higher, the internal stress could be lower

Melt resin temperature: increase the melt resin temperature could reduce the internal stress. For PC material, the melt temperature could be 260-330 degrees Celsius, if higher, the internal stress could be lower

Injection pressure: PC material have high viscosity, seems need high injection pressure. But high injection pressure will increase the internal pressure. So high injection pressure is not suitable if part with PC material have crack already

Injection speed: high speed will increase the crack risk. lower injection speed is required if part need lower internal stress

留言