Review contents after the plastic mold trial (7)--Runner system

- Jussi Zhong / plastic mold expert in Shenzhen

- 2015年10月21日

- 讀畢需時 1 分鐘

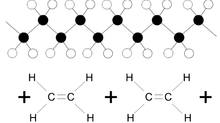

Runner in the plastic mold is the road for the melt resin, from the injection machine nozzle to the mold gate. We need consider how to save the resin material and injection pressure on this road?

Whether it is collect for the runner shape

Consider the size of the runner, whether it's satisfy with the melt resin flow

Is the run length suitable for the resin flow?

Are there cold-slug well at the end of the runner?

Are there radius where the runner joint together?

Is roughness of the runner surfaces right?

Do the sprue radius and its hole size match with the nozzle of the injection machine?

Do the runner stick to the core or cavity?

The time of the runner cooling is appropriate?

Main runner draft angle is OK?

Eject system for runner is suitable? need consider the efficiency of the eject

Are there any shaving powder generated?

Observe the plastic cosmetic surfaces, are there any cold plastic? To consider whether suitable of the cold slug well size and position

Are there flash on the runner?

留言