Determine an unqualified plastic mold (3)

- Jussi zhong / plastic mold expert in Shenzhen

- 2015年10月21日

- 讀畢需時 1 分鐘

To determine a mold, except to inspect plastic parts, sometimes assemble them and use in the reality .

There are not glossy, have cold plastic, hard spots, pits on the part surfaces

Appear flash and shrinkage on the part at same time, or appear shrinkage and eject white mark at same time, and not easy to improve

There are drag mark, flash, shortage, drag white mark etc. at the side of page

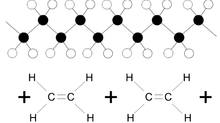

The thickness of part is not even, too big or too thin. ( too big is easy to shrinkage, too thin is easy to be broken and difficult to fill for the melt resin)

The part structure, part dimension, precision don't match the drawing requirements, there are obvious gap or misplacement when assemble parts

Internal stress is big, easy to be deformation and stress crack

留言