Determine an unqualified plastic mold (2)

- Jussi Zhong / plastic mold expert in Shenzhen

- 2015年10月21日

- 讀畢需時 1 分鐘

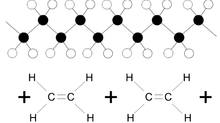

All of us wouldn't face the unqualified plastic mold, most of them are caused by the tiny issues you didn't pay attention to. After mold trial, we can inspect the plastic parts and its mold.

Ribs, cylinders or gate (sometimes runner) stick to the cavity or core, perhaps there are gate broken in the molding

sliders ( stroke is not enough ), guide pin, lifter are not smooth when they are in the moving, mold often are damaged or breakdown for that

The screw cylinder, there are off center, drag mark, broken or deformation

Gate is not easy released from the plastic parts, wasting the labor cost. And on the gate position, there are shortage, remnant, flash, sharp, broken defect phenomenon

There are flow mark, water ripples on the part surfaces

There are burnt mark, air trap, shortage on the parts

留言