Review contents after the plastic mold trial (1)--Gate position

- Jussi Zhong / plastic mold expert in Shenzhen

- 2015年10月20日

- 讀畢需時 1 分鐘

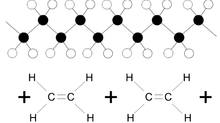

For a plastic mold, No matter you imagine how importance of gate, it's not excessive. We need consider the gate style, quality, position and its dimensions. What's the elements we need consider when put the gates on the plastic parts ?

Is it necessary to be put on the thickest thickness of wall?

Does gate position affect the melt resin to flow ability ( Flow length ratio to be checked )

Benefit for the air venting?

Is the gate right in the front of the inserts? ( prevent the melt resin impact and move the inserts )

On the plastic parts, the gate position is the stressed position? when the plastic parts used ( prevent the stresses on the plastic parts to be broken)

Is there possible to be unbalance for the melt resin flow inside the plastic parts?

Does the gate position affect the deformation of the plastic part?

We need consider the compensation of injection in the holding pressure processing.

Is it convenient to cut the gate after the molding?

Cosmetic surfaces if accepted after the gate cut?

Is the remnant gate acceptable if the gate style is the point gate?

Is it balance of the injection pressure on the whole mold parting line surfaces if this mold is multiple cavities?

There are welding lines on the parts, these welding lines are on the stress places when plastic parts used?

留言